公司是一家专业从事阀门产品的研制、开发、制造、检测、销售于一体的*;是上海,通过ISO9001-2008质量体系认证,国家质量技术监督检验疫总局特种设备制造许可“TS”认证。

| 美标阀门 | |

| |  | | 性能规范: | | 公称压力PN | 150 | 300 | 600 | Lb | | 壳体试验压力PT | 3.0 | 7.8 | 15.4 | MPa | | 密封试验压力 | 2.2 | 5.6 | 11.2 | | 气密封试验压力 | 0.5~0.7 | | 适用介质 | 水、油品、蒸汽酸类 | | 适用温度 | ≤427℃ |

|

|

| |

| | | |

| |  | | 执行标准: | | 设计标准 | ANSI、B16.34、API、600 | | 结构长度 | ANSI、B16.10 | | 法兰连接 | ANSI、B16.5 | | 检验与试验 | API598 |

|

|

| |

| | | |

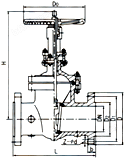

| | [Z40、Z41型、150Lb、300Lb、600Lb楔式闸阀]主要外形尺寸与连接尺寸 (单位:毫米) | |

| | 磅级

Class | 公称通径DN | 单位 | 尺 寸 | | in | mm | L | H(全开) | D | D1 | D2 | b | Z-φd | D0 | | 150Lb | 2 | 50 | in | 7.00 | 16.10 | 6.00 | 4.75 | 3.62 | 0.75 | 4-0.75 | 8.00 | | mm | 178 | 409 | 152 | 120.5 | 92 | 19.1 | 4-19 | 200 | | 3 | 80 | in | 8.00 | 20.00 | 7.50 | 6.00 | 5.00 | 0.94 | 4-0.75 | 10.00 | | mm | 203 | 570 | 190 | 152.5 | 127 | 23.9 | 4-19 | 250 | | 4 | 100 | in | 9.00 | 23.20 | 9.00 | 7.50 | 6.19 | 0.94 | 8-0.75 | 10.00 | | mm | 229 | 590 | 229 | 190.5 | 157 | 23.9 | 8-19 | 250 | | 6 | 150 | in | 10.50 | 24.80 | 11.00 | 9.50 | 8.50 | 1.00 | 8-0.88 | 12.00 | | mm | 267 | 630 | 279 | 241.5 | 216 | 25.4 | 8-22 | 300 | | 8 | 200 | in | 11.50 | 37.80 | 13.50 | 11.75 | 10.62 | 1.12 | 8-0.88 | 13.88 | | mm | 292 | 960 | 343 | 298.5 | 270 | 28.5 | 8-22 | 350 | | 10 | 250 | in | 13.00 | 45.60 | 16.00 | 14.25 | 12.75 | 1.19 | 12-1.00 | 15.70 | | mm | 330 | 1158 | 406 | 362 | 324 | 30.2 | 12-25 | 400 | | 12 | 300 | in | 14.00 | 54.30 | 19.00 | 17.00 | 15.00 | 1.25 | 12-1.00 | 17.70 | | mm | 356 | 1378 | 483 | 432 | 381 | 31.8 | 12-25 | 450 | | 14 | 350 | in | 15.00 | 60.75 | 21.00 | 18.75 | 16.25 | 1.38 | 12-1.12 | 19.70 | | mm | 381 | 1543 | 533 | 476 | 413 | 35 | 12-29 | 500 | | 16 | 400 | in | 16.00 | 68.40 | 23.50 | 21.25 | 18.50 | 1.44 | 12-1.12 | 23.60 | | mm | 406 | 1738 | 597 | 540 | 470 | 36.6 | 16-29 | 600 | | 18 | 450 | in | 17.00 | 71.10 | 25.00 | 22.75 | 21.00 | 1.56 | 16-1.25 | 23.60 | | mm | 432 | 1959 | 635 | 578 | 533 | 39.7 | 16-32 | 600 | | 20 | 500 | in | 18.00 | 87.20 | 27.50 | 25.00 | 23.00 | 1.69 | 20-1.25 | 26.80 | | mm | 457 | 2214 | 698 | 635 | 584 | 42.9 | 20-32 | 680 | | 24 | 600 | in | 20.00 | 102.3 | 32.00 | 29.50 | 27.25 | 1.88 | 20-1.38 | 29.90 | | mm | 508 | 2599 | 813 | 749.5 | 692 | 47.7 | 20-35 | 760 | | 30 | 750 | in | 24.00 | 125.3 | 38.75 | 36.00 | 33.75 | 2.94 | 28-1.38 | 36.00 | | mm | 610 | 3183 | 984 | 914.5 | 857 | 74.5 | 28-35 | 915 | | 36 | 900 | in | 28.00 | 147.00 | 46.00 | 42.75 | 40.25 | 3.56 | 32-1.62 | 36.00 | | mm | 711 | 3737 | 1170 | 1086 | 1022 | 90.5 | 32-41 | 915 | | 300Lb | 2 | 50 | in | 8.50 | 16.70 | 6.50 | 5.00 | 3.62 | 0.88 | 8-0.75 | 8.0 | | mm | 216 | 424 | 165 | 127 | 92 | 22.3 | 8-19 | 200 | | 3 | 80 | in | 11.15 | 21.00 | 8.25 | 6.62 | 5.0 | 1.12 | 8-0.88 | 10 | | mm | 283 | 535 | 210 | 168.5 | 127 | 28.5 | 8-22 | 250 | | 4 | 100 | in | 12.00 | 24.20 | 10.0 | 7.88 | 6.19 | 1.25 | 8-0.88 | 10 | | mm | 305 | 615 | 254 | 200 | 157 | 31.8 | 8-22 | 250 | | 6 | 150 | in | 15.87 | 31.30 | 12.50 | 10.62 | 8.5 | 1.44 | 8-0.88 | 14 | | mm | 403 | 795 | 318 | 270 | 216 | 36.6 | 12-22 | 350 | | 8 | 200 | in | 16.50 | 39.90 | 15.0 | 13.0 | 10.62 | 1.62 | 12-1.0 | 15.7 | | mm | 419 | 1012 | 381 | 330 | 270 | 41.3 | 12-25 | 400 | | 10 | 250 | in | 18.00 | 48.50 | 17.50 | 15.25 | 12.75 | 1.88 | 16-1.12 | 17.7 | | mm | 457 | 1231 | 444 | 387.5 | 324 | 47.7 | 16-29 | 450 | | 12 | 300 | in | 19.75 | 57.0 | 20.50 | 17.75 | 15.0 | 2.00 | 16-1.25 | 19.7 | | mm | 502 | 1450 | 521 | 451 | 381 | 50.8 | 16-32 | 500 | | 14 | 350 | in | 30.00 | 64.8 | 23.00 | 20.25 | 16.25 | 2.12 | 20-1.25 | 23.6 | | mm | 762 | 1645 | 584 | 514.5 | 413 | 54.0 | 20-32 | 600 | | 16 | 400 | in | 33.00 | 72.50 | 25.50 | 20.25 | 18.5 | 2.25 | 20-1.38 | 23.6 | | mm | 838 | 1841 | 648 | 571.5 | 470 | 57.2 | 20-35 | 600 | | 18 | 450 | in | 36.00 | 76.50 | 28.00 | 24.75 | 21 | 2.38 | 24-1.38 | 26.8 | | mm | 914 | 1943 | 711 | 628.5 | 533 | 60.4 | 24-35 | 680 | | 20 | 500 | in | 39.00 | 84.8 | 30.50 | 27.0 | 23.0 | 2.50 | 24-1.38 | 38 | | mm | 991 | 2154 | 775 | 686 | 584 | 63.5 | 24-35 | 760 | | 24 | 600 | in | 45.00 | 100.50 | 36.0 | 32.0 | 27.25 | 2.75 | 24-1.62 | 36 | | mm | 1143 | 2553 | 914 | 813 | 692 | 69.9 | 24-41 | 915 | | 600Lb | 2 | 50 | in | 11.50 | 18 | 6.5 | 5.00 | 3.62 | 1.0 | 8-0.75 | 10 | | mm | 292 | 458 | 165 | 127 | 92 | 25.4 | 8-19 | 250 | | 3 | 80 | in | 14.00 | 22.58 | 8.25 | 6.62 | 5.00 | 1.25 | 8-0.88 | 10 | | mm | 356 | 570 | 210 | 168 | 127 | 31.8 | 8-22 | 250 | | 4 | 100 | in | 17.00 | 27.2 | 10.75 | 8.50 | 6.19 | 1.5 | 8-1.0 | 14 | | mm | 432 | 690 | 273 | 216 | 157 | 38.1 | 8-25 | 350 | | 6 | 150 | in | 22 | 35.8 | 14 | 11.50 | 8.50 | 1.88 | 12-1.12 | 18 | | mm | 559 | 910 | 356 | 292 | 216 | 47.7 | 12-29 | 450 | | 8 | 200 | in | 26.00 | 41.9 | 16.5 | 13.75 | 10.62 | 2.19 | 12-1.25 | 19.7 | | mm | 660 | 1064 | 419 | 349 | 270 | 55.6 | 12-32 | 500 | | 10 | 250 | in | 31.00 | 49.5 | 20 | 17.00 | 12.75 | 2.5 | 16-1.38 | 23.6 | | mm | 787 | 1257 | 508 | 432 | 324 | 63.5 | 16-35 | 600 | | 12 | 300 | in | 33 | 57.8 | 22 | 19.25 | 15.00 | 2.62 | 20-1.38 | 26.8 | | mm | 838 | 1468 | 559 | 489 | 381 | 66.7 | 20-35 | 680 | | 14 | 350 | in | 35 | 63.9 | 23.75 | 20.75 | 16.25 | 2.75 | 20-1.50 | 26.9 | | mm | 889 | 1623 | 603 | 527 | 413 | 69.9 | 20-38 | 760 | | 16 | 400 | in | 39 | 71.5 | 27 | 23.75 | 18.5 | 3.0 | 20-1.62 | 26.9 | | mm | 991 | 1816 | 686 | 603 | 470 | 76.2 | 20-41 | 760 | | 18 | 450 | in | 43 | 82.7 | 29.25 | 25.75 | 21.00 | 3.25 | 20-10.75 | 36 | | mm | 1092 | 2100 | 743 | 654 | 533 | 82.6 | 20-44 | 915 | | 20 | 500 | in | 47 | 88.6 | 32 | 28.5 | 23.00 | 3.5 | 24-1.75 | 37.4 | | mm | 1194 | 2250 | 813 | 724 | 584 | 88.9 | 24-44 | 950 | | 24 | 600 | in | 55 | 107.5 | 37 | 33.0 | 27.25 | 4.0 | 24-2.0 | 39.4 | | mm | 1397 | 2730 | 940 | 838 | 692 | 102 | 24-52 | 1000 |

| |

订货须知:(国家标准)

一、A:产品名称、型号、公称通径B:介质及温度、压力范围C:是否有附件、交货期、特殊要求等以便我们的为您正确选型。

二、若已经由设计单位选定我公司的阀门型号,请您根据阀门参数直接与我们销售中心订购。

三、当您使用的场合非常重要或环境比较复杂时,请您提供设计图纸和详细参数,我们的工程师专家会专心为您审核与分析。

我们可以为您提供专业的解决方案,包括设计、定做、成套、运行、服务。我们一直致力于阀门行业领域的*,为您提供的阀门知识、的服务、*的技术顾问。如有任何疑问,您可以致电给我们,我们一定会尽心尽力为您提供优质的服务。我们立志成为世界的阀门制造商。